There are many types of blind threaded inserts that benefit both design and manufacturing engineers. Blind-installed threaded fasteners have internal or external threads that can be installed into a panel, tube or other structure from the front side without having to see or access the backside, or “blind” side, to complete the installation. Once installed, inserts remain captive so that a mating component can be attached using standard hardware.

Knowing how to select the correct insert is important for the design and strength of the application.

Selecting the right blind-installed insert for the application involves many factors. AVK Industrial Products offers many types of blind threaded inserts with numerous advantages unique to the industry.

Benefits

- Access to only one side of the parent material is rqurie

- Ease of installation

- Ease of assembly

- Load bearing thread allow use of thinner materials

- Installation is accomplished after material is finished (painted, anodized, etc.)

- Portable, light weight power tools are conveniently placed anywhere in the assembly line

- Eliminate tapping

- Installs after sheet material is formed

- Increase product integrity

- Wide grip range

- Minimize material handling

- Installation holes may be closed to the edge of the sheet

- Works in many types of materials

- Use unskilled labor for installation

- Low in-place cost

- Eliminates handling of large items

- Vibration proof

- Wear resistant threads

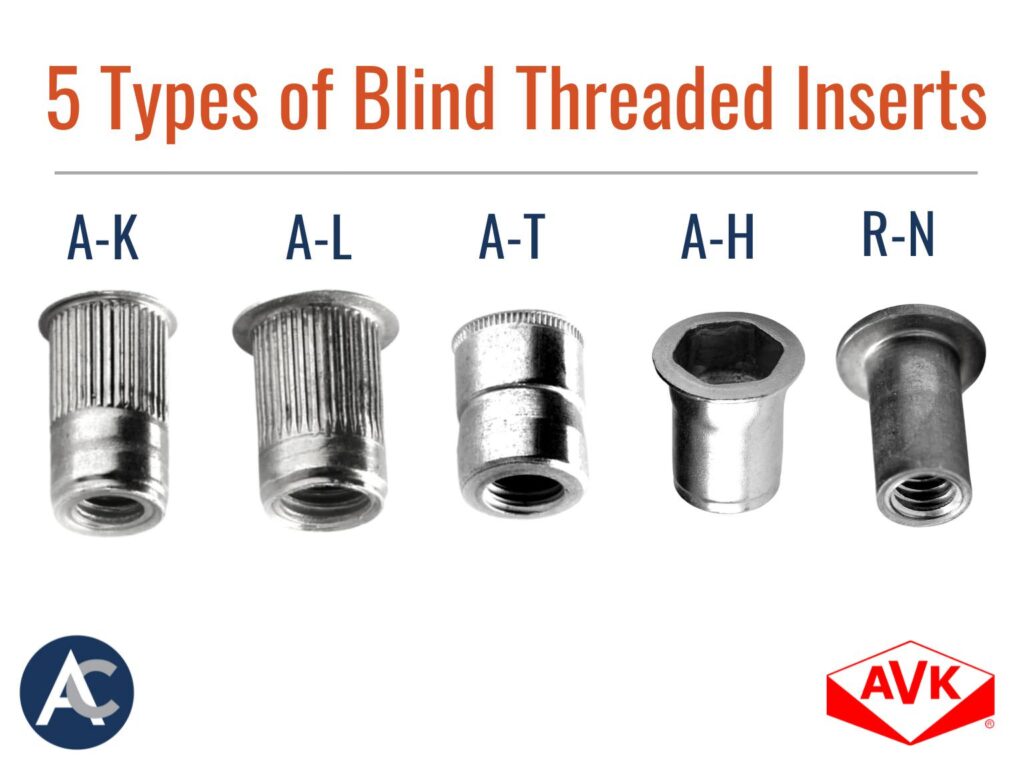

5 Popular Types of Blind Threaded Inserts

A-K Series Inserts by AVK have exceptionally strong torque-out and pull-out characteristics. A-K blind threaded inserts are very effective in very thin, as well as, thick sheet metal, in both blind and open applications.

A-L Series Inserts have a large head for applications where large or irregular holes are a problem. A-L Series blind threaded inserts can be installed in sheet metal, structural foam, fiberglass and some plastics.

A-T Series Inserts by AVK are the “non-grip sensitive” inserts that will work in “any” thickness over .030. The installation tool pulls the “cone” shaped nut into a sleeve expanding into the parent material.

A-H Series Threaded Hex Inserts feature a radius corner hex body. When installed into a hex hole, the radius corners of the hex insert expand and fill the hole corners providing exceptional resistance to spinning in the panel.

R-N Series Rivet Nut Threaded Inserts feature a heavy duty head profile and increased wall thickness in the collapse area. The R-N Inserts are ideal for leg leveling.

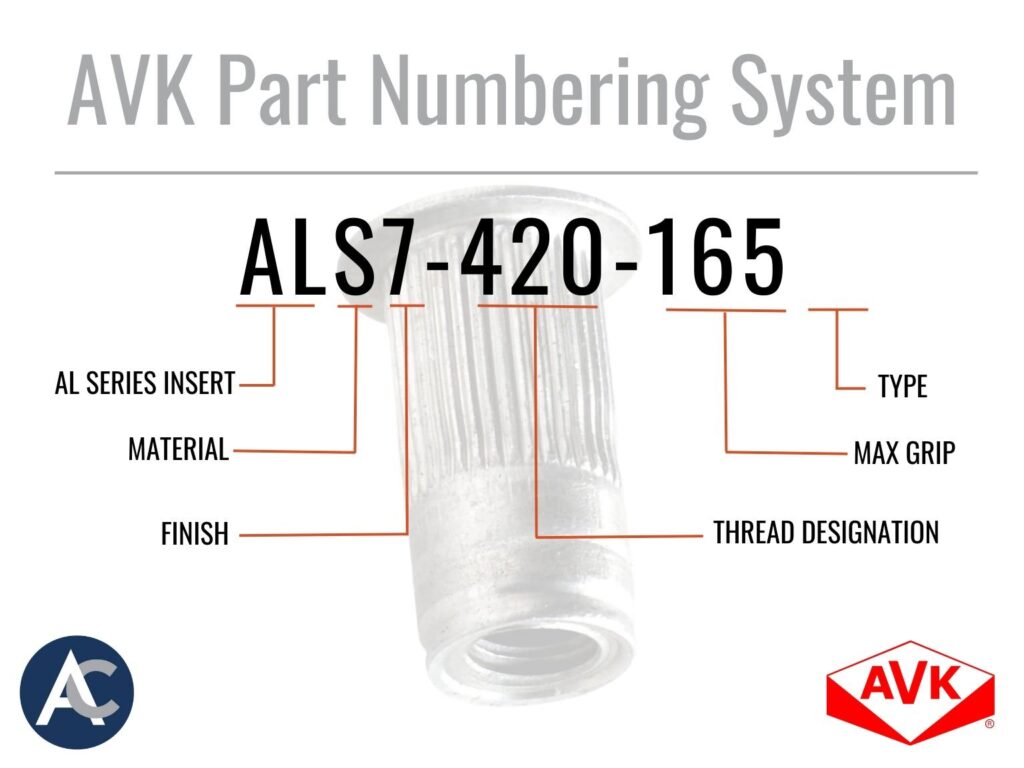

How to Read AVK Insert Part Numbers

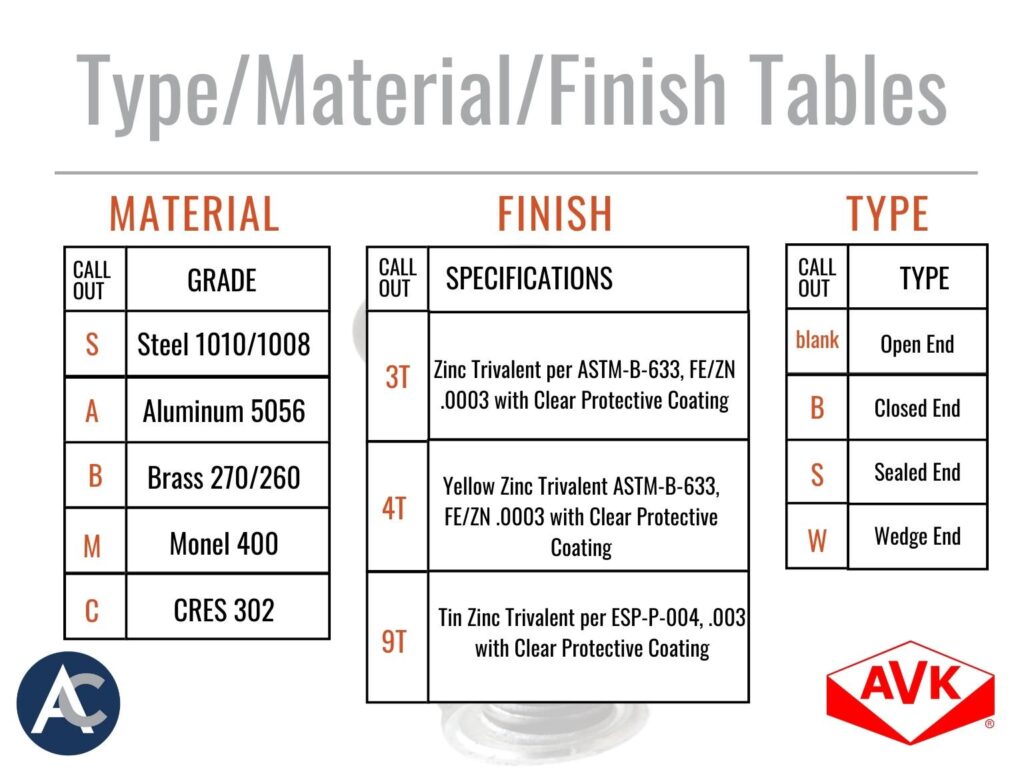

Each AVK Blind Threaded Insert has a series of letters and numbers that identify the series, material, finish, type, max grip and thread designation. Once you understand what each number or letter means, selecting the correct fastener for the job will be easy.

About AVK

AVK Industrial Products is located in Southern California. AVK manufactures blind installed threaded fasteners for transportation and general industrial markets throughout the world. Advance Components has been a master stocking distributor of AVK inserts and installation tools for 38 years. The Advance Team is highly trained in AVK applications and tool repair.