When it comes to choosing tools for installing commercial blind rivets, the choices can be confusing and expensive. Different fasteners require a tool and a nose assembly that will work together to create a secure connection.

Gage Bilt manufactures a variety of installation tools for commercial rivets and lockbolts, and aerospace rivets and lockbolts. Today we will be discussing economic and ergonomic tools that are recommended for the installation of commercial blind rivets.

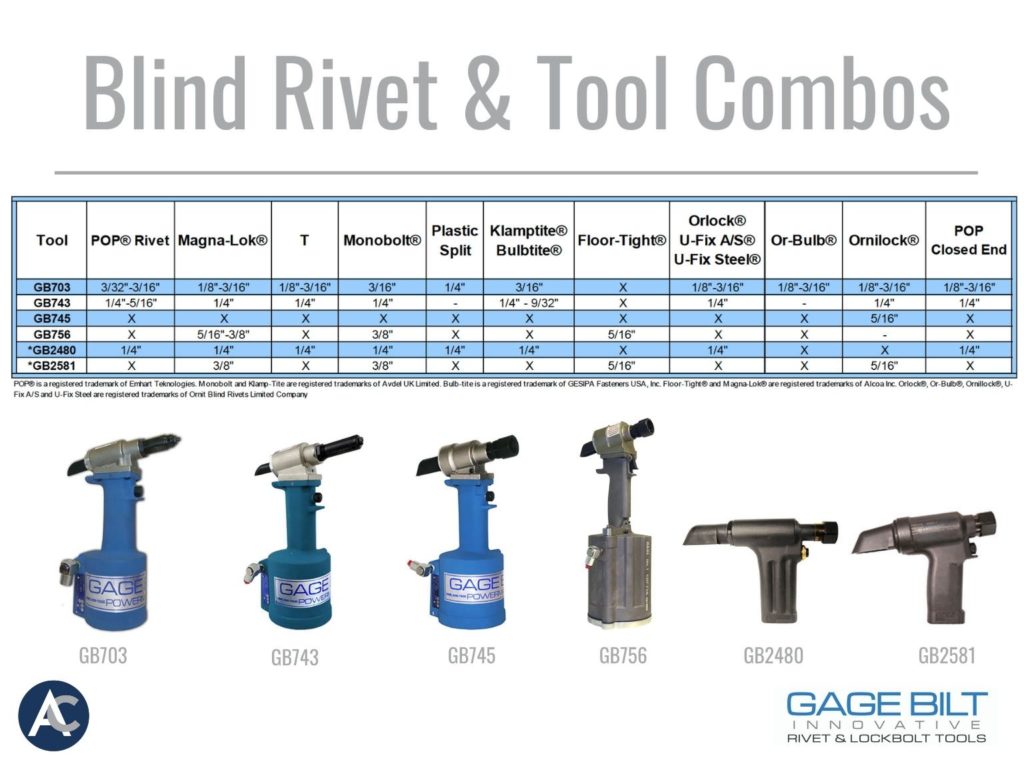

Common Blind Rivets and Rivet Tools Combinations

Gage Bilt pneudraulic (pneumatic-hydraulic) and hydraulic installation tools are lightweight and ergonomic, so they can be used with one hand in any position. They are also very versatile when it comes to installing a variety of commercial blind rivets.

In the chart below are some of the most common recommendations for commercial rivets and Gage Bilt installation tools. Keep in mind these tools install a variety of rivets. Please check the individual tool fliers for a complete list of nose assemblies and fasteners that the tools will install.

The Gage Bilt Advantage

When it comes to choosing rivet installation tools, Gage Bilt has many advantages over other brands. Both maintenance of the tools and ease of operation are important when deciding what tool to use.

Maintenance Advantages

Gage Bilt vs. HUCK®

Easy to bleed vs. difficult to bleed

Less moving parts vs. more parts, more inventory & more failure

Screw in air trigger vs. cable assembly subject to failure

One metal base cover vs. plastic base cover subject to breakage

Air return piston vs. spring return subject to failure

Gage Bilt vs.POP®

Easy to bleed (10 secs) vs. difficult to bleed (10 minutes)

Less moving parts vs. more parts, more inventory & possible failure

Screw in air trigger vs. complicated spring linkage

Air piston return vs. spring return subject to failure

Gage Bilt vs. Avdel® and Cherry®

One piece piston vs. two pieces (pintail jams)

One piece screw on base cover vs. three pieces (retaining rings)

Easy to remove valve pin vs. retaining ring becomes embedded into handle

One piece deflector vs. three pieces

Less moving parts vs. more parts, more inventory, possible failure

Internal hex in piston (most tools) vs. None: could cause the piston to strip and scar; hard to tighten right angle and offset noses.

Operator Advantages

Gage Bilt vs. Avdel® and Cherry®

The one piece piston in Gage Bilt tools jam less than other tools. The bendable deflector is safer for the operator as they are less likely to remove it. There is much less downtime with solid Gage Bilt tools vs. Avdel® and Cherry® plastic tools.

Gage Bilt vs. HUCK® and POP®

The low effort trigger on Gage Bilt rivet tools reduces operator fatigue and carpal tunnel syndrome. The air return reduces head envelope, and the longer stroke tools facilitate single stroke installations. Compared with HUCK® or POP® installation tools, Gage Bilt tools are constructed so that the operator will be less likely to remove the deflector safety system.

Innovative Solutions

Gage Bilt is committed to manufacturing commercial rivet installation tools that make installing fasteners easy and economical. Advance is a master distributor of Gage Bilt tools. We carry a large inventory of tools, nose assemblies, power units and components for commercial rivet and lockbolt installations. The Advance sales team is trained in Gage Bilt tools and applications. Contact us for your Gage Bilt solution.