Hose clamps for marine use should be made from high-grade stainless steel to resist corrosion so they won’t rust and fail. The best hose clamps for boats should be manufactured from 316 stainless steel, as well as the screw and gear housing. It’s always important to keep in mind that not all stainless steel is the same, as less expensive clamps made of 304 stainless doesn’t contain molybdenum which can make it more prone to corrosion.

A good way to check for quality stainless steel is to use a magnet. High quality stainless steel clamps, screws and gear housing will not stick to the magnet.

Investing in quality hose clamps is essential for the protection of your boat investment and possibly your safety. According to GEICO/BoatUs Marine insurance claim files, more than 40% of boat sinkings happen while the boat is tied to the dock. Many claims filed show the sinking was due to a detached or loose hose, showing how important something as small as a hose clamp can be to the life of your boat.

The IFE Way

Over 100 years ago in 1903, IFE developed their first marine inboard engine in the Swedish Archipelago. They exited the engine manufacturing business in the 1930s and began making components for fluid systems in the 1960s. Never losing their passion for the marine industry, IFE continues to manufacture hose clamps and coupling products that are found in pleasure and work boats worldwide.

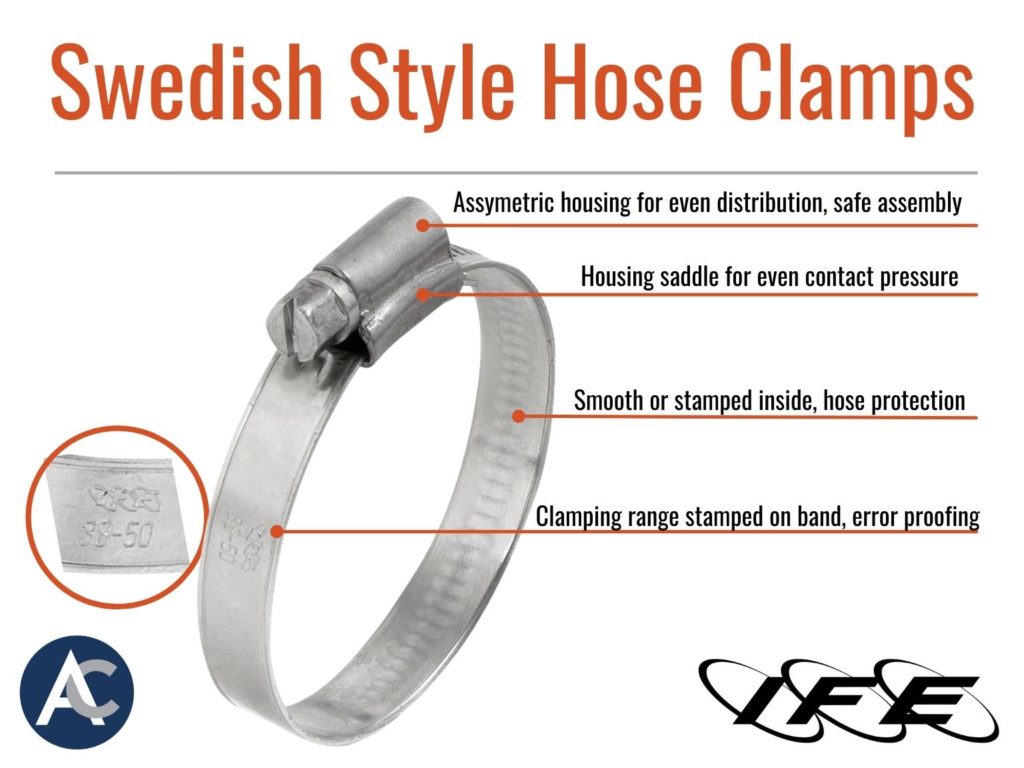

Swedish Style

Made of the highest quality 316 stainless steel, IFE’s Swedish style worm drive hose clamps are used throughout the industry by OEM boat builders and refitters. The clamps have a solid band with embossed threads and a smooth underside that resists corrosion. The smooth band is virtually impervious to overtightening and stripping unlike some perforated clamps. The rounded edges protect the hose against damage and ensure a perfect seal.

Swedish-style clamps have housings that are formed from a tube for strength, and a one piece design that ensures high destruction torques and reliability.

Smooth vs. Perforated

Both smooth and perforated worm drive or worm-gear hose clamps have been around for years. The simple design of a band, a gear housing and screw, effectively exerts uniform pressure on hoses and their fittings. It wet or high-rust conditions, smooth clamps have an advantage over perforated clamps.

Perforated

Many perforated hose clamps rely on a series of perforations cut into the band to engage with the screw threads. These perforations can elongate when tensioned and cause microcracking, corrosion and metal decay.

When these clamps part, it often happens across one of the perforated holes. And the holes can also cause damage to the hose jacket, sometimes squeezing out pieces of the hose in the perforations.

Smooth

Smooth bands such as the IFE Swedish style clamp, eliminates possible damage due to perforations overstressing or squeezing the hose into a pulpy mess. The stamped/embossed threads resists elongation, cracking and stripping. Swedish style hose clamps are virtually immune to stripping even when overtightened.

The smooth interior eliminates hose damage caused by perforated clamps, and the slightly rounded edges are gentler on hoses. When submerged or exposed to water, 316 stainless steel Swedish style clamps resist corrosion and the possibility of a hose becoming loose or detached.

In Stock Solutions

Advance Components is a master stocking distributor of IFE Americas USA worm drive hose clamps including American style and German style clamps. Advance does not stock Swedish style hose clamps currently, but we are happy to source them for you. IFE clamps are used in a variety of applications in the marine industry such as:

- Fuel lines

- Sanitary lines

- Oil lines

- Ventilation systems

The Advance sales team is trained in applications for IFE clamps and is available to assist with support, quotes, and samples. Contact Advance for more information or buy online 24/7.