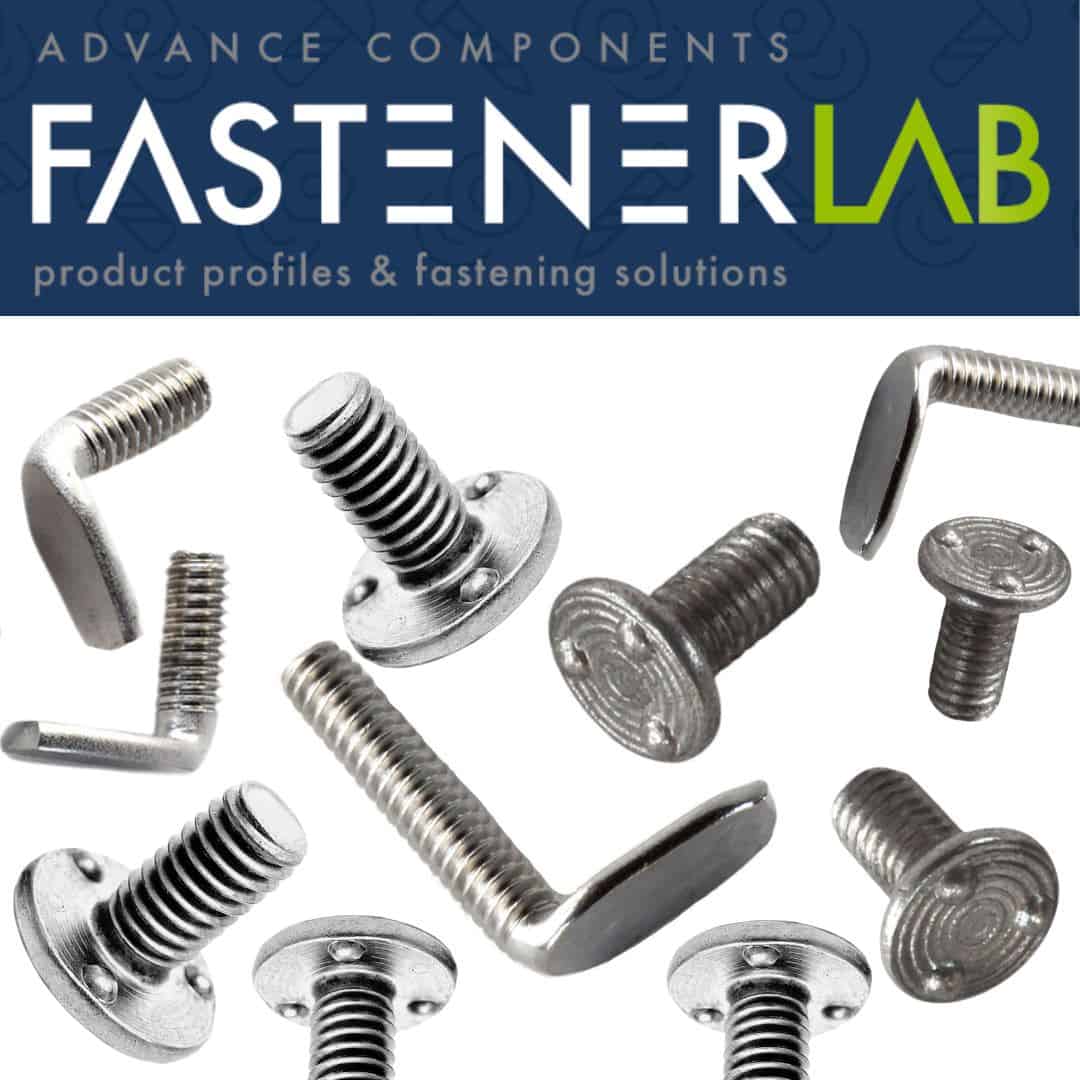

Weld Screws are designed to be permanently welded to like materials, and are available in low carbon, stainless steel, heat-treated and plated. There are variety of styles, but the most common are these three styles of weld screws: small metal projections on top of the screw head; on the underside or bottom of the screw head; and the right angle weld screw. Most styles are ideal for applications in confined areas.

Weld Screws are ideal for providing quick, strong and permanent bonds to metal surfaces.

Weld Screws: Projections on Top of Screw Head

Weld screws with three projections on top the head enable secure welding directly to the sheet surface – no holes required. When attached, weld screws with 3 prongs on the head leave the exterior surface virtually unblemished, ensuring a flawless finish. Top projection weld screws are ideal in blind location applications, and can be permanently pre-attached, granting unparalleled accessibility even in the tightest of spaces.

Benefits:

- Facilitates weld nugget formation directly on the sheet surface

- No holes need to be drilled or punched through the material

- Ideal for applications where a clean exterior surface is desired with no protrusions

- Great for appearance/aesthetic reasons or to prevent potential leakage

Weld Screws: Projections Under the Screw Head

Screws with projections on the bottom of the screw head require pre-drilled holes in the top of the sheet for insertion to create a flush mount. The projections on the weld nut get welded through the holes to the bottom sheet and creates a protrusion on the top surface where the screw head sit. They are ideal for joining two overlapping sheets securely.

Benefits:

- Optimum positioning an balance

- Secure joins overlapping sheets

- Self-locating

- Eliminate need for fixturing

Weld Screws: Right Angle

Right angle weld screws, also known as spade or dogleg weld screws, have a unique design that sets them apart from other conventional weld screws. Right angle/spade screws give the installer the ability to access tight spots and weld onto exposed surfaces. The threads are offset at an angle which provide flexibility that straight weld screws cannot.

Benefits:

- Can be offset from the welding surface.

- Accessible in tight spaces, corners, and narrow channels where a straight screw cannot fit.

- Confined areas while the welding surface remains exposed.

- Ideal for welding in restrictive locations like tubular frames.

- Allows welding to occur on exposed flat surfaces

Buckeye Fasteners

Buckeye Fasteners is a domestic manufacturer of weld screws, weld nuts and weld pins for the automotive, appliance, food equipment, medical, furniture and metalworking industries. Advance Components is a master stocking distributor for Buckeye Fasteners, and offers our customers a wide variety of weld fasteners that are available to purchase online 24/7.