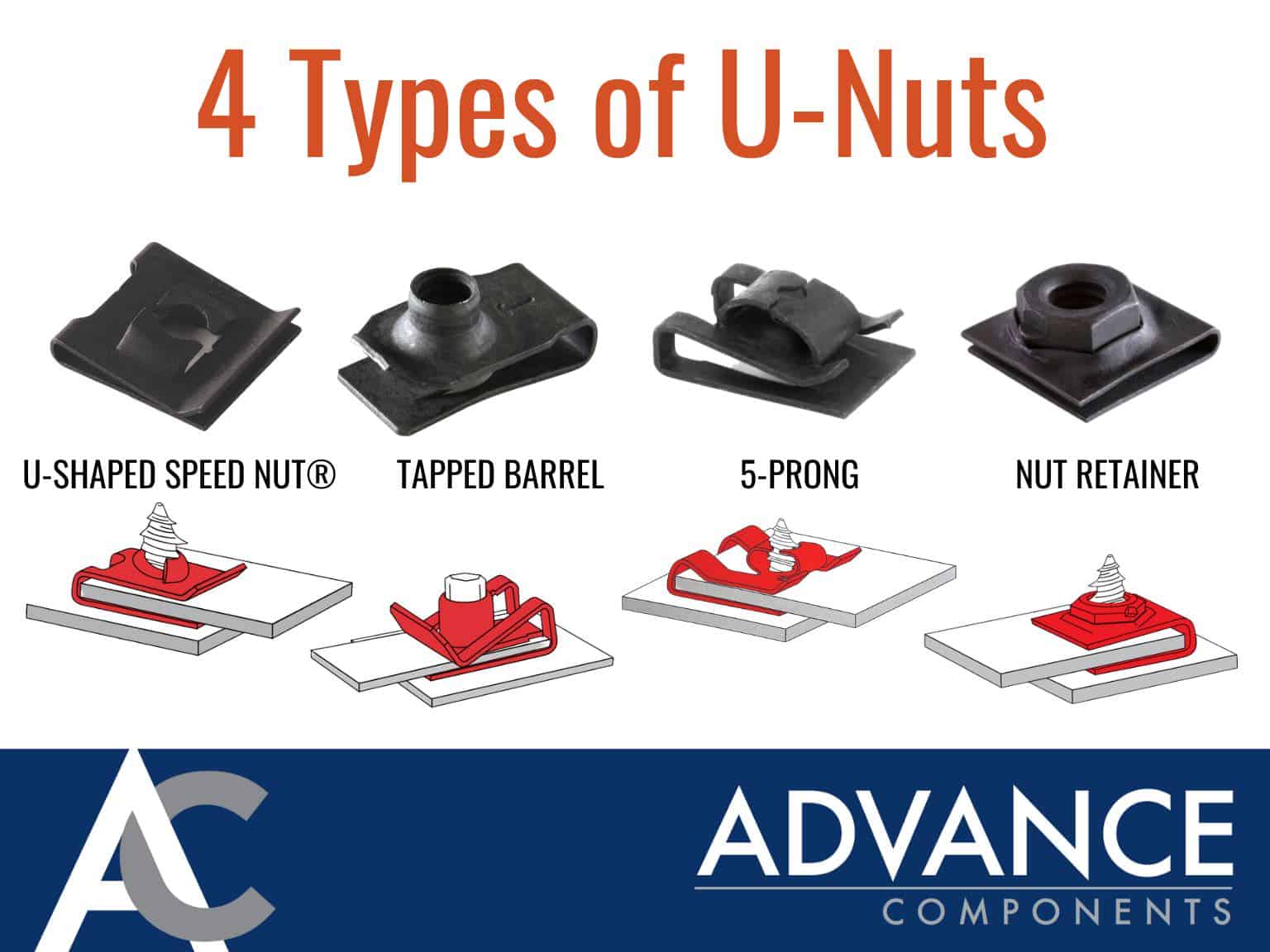

U-Nuts are self-retaining fasteners that stay in a screw-receiving position to provide a rapid and simple attachment of mating panel assemblies. Today in FastenerLab we are looking at the most commonly used types of U-Nut fasteners: single impression U-shaped Speed Nuts®, a 5-prong style, threaded barrel style, and nut retainers – two-piece assemblies that combine the strength of a cold-headed nut with the versatility of a sheet metal cage.

U-Nuts do not turn as the screw is driven into place and correct misalignment in panel mounting holes.

All types of U-Nut fasteners can be used wherever a screw or bolt is used and are used in place of clinch-nuts and weld-nuts. They reduce strip-outs, increase joint integrity and prevent panel damage caused by misalignment.

Which U-Nut To Use

Selecting the right U-Nut for the job requires selecting the thread specification needed for the desired joint strength and panel thickness. The U-Nut must accommodate the distance from the edge of the panel to the center line of the mounting hole.

U-Nuts can work in many applications. The strength of the connection greatly depends on the type of impression and the size of the screw. The single impression U-shaped Speed Nut® is ideal for lighter duty applications, while the 5-pronged U-Nut provides a more secure connection with course thread screws, as the five prongs increases the prevailing torque to eliminate destruction. Both types of U-Nuts are easy to install and have lower profiles which creates a cleaner joint.

Threaded tapped barrel U-Nuts are ideal for machine screw applications because the tapped barrel strength is equal to that of the screw. The barrel of the U-Nut comes in prevailing torque and free-spinning options which makes it an ideal type of U-Nut for heavier applications.

For larger screw size applications, Nut Retainers are recommended. The nut easily slides over the panel edge and the panel hole, and provides a secure connection. They combine the flexibility of a spring steel cage with the strength of a steel nut.

Industries & Applications

- Appliances

- HVAC

- Automotive

- Electronics

- Furniture

- Marine

- Utility Vehicles

- Lighting Equipment

Benefits

- Self-retaining – stays in screw receiving position

- Easy to assemble – requires no special tools

- Serviceable – parts disassemble easily and reliably

- Design – single component eliminates small parts handling and reduces parts inventory

- Cost saving – improves assembly time

- Time saving – eliminates weld nuts and clinch nuts

- Corrective – no misalignment in panel mounting holes

- Strong – does not turn as screw is driven, no freezing on threads

These types of U-Nut fasteners are all manufactured by ARaymond/Tinnerman. Since 1972 Advance has been stocking and distributing a large variety of U-Nuts. The Advance sales team is highly trained in all applications for U-Nuts, whether for appliances, construction, furniture, electronic or marine – we have the U-Nut solution for you. Buy online or contact us for support, service, quotes and samples.