To Drill or to Hammer?

That is the Question

Duplex Screws and Duplex Nails are flanged-head or double-headed fasteners that are often used to build temporary structures such as braces, scaffolding and concrete formwork. They are designed to be easily removed, so they don’t go completely into the wood during installation.

First Came the Nail

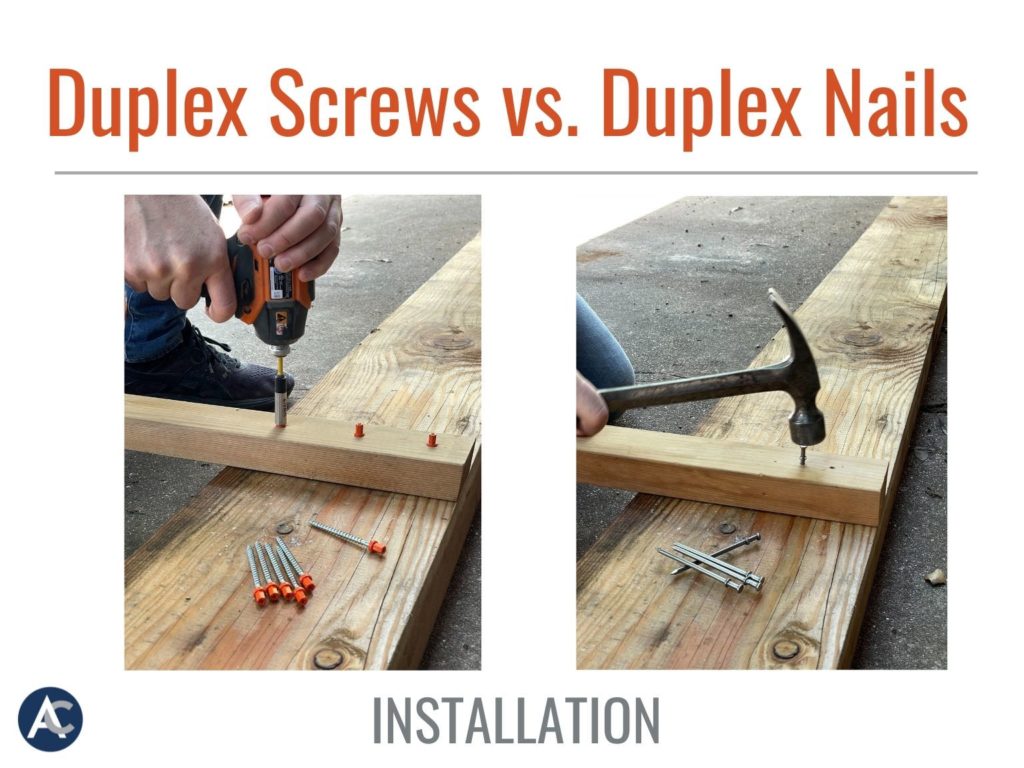

Duplex Nails are as strong as regular nails, but the double head makes them easier to remove with a claw hammer or crowbar. Workers drive the nail until the lower flange is flush with the material. With a pull bar or reverse end of a claw hammer, the nails pull out after the job is finished. Depending on the application, if too much force or bending is required to remove the nails, they are often not reusable.

William Arthur Collings of Kansas City, Mo., received a patent for the Duplex Nail in 1917. His description detailed how the double-headed nail was ideal for use on concrete forms because it was easy to remove, compared to regular nails, without damaging the forms.

Collings wrote: “After the concrete has set sufficiently, the forms are removed, but due to the fact that the heads of the nails are driven into the wood, it is very difficult to remove the nails without damage being done to the forms, which frequently have to be broken and even smashed to pieces in their removal, thus causing a considerable waste of material and loss of time.”

Today there are a large variety of styles and sizes of Duplex Nails made by manufacturers worldwide. Your local hardware store probably sells Duplex Nails as they are almost as common as regular nails.

Then Came the Screw

Duplex Screws feature a double-hex head, which accepts a variety of driving tools — a pile driver or hex-head screwdriver — for installation, and removal after use. The driver drills the orange hex-head screw until the stop flange is flush with the material and can easily remove it by reversing the drill. Since there is no need to force the removal, the screw maintains its shape and can be reused multiple times.

Duplex Screws were patented in 2007 by Daniel Carrillo Sr., and Hector Carrillo of California, and the patent was assigned to Removerite Inc. in 2013. In their application, the Carrillos said that the Duplex Screw is ideal for concrete formwork and better than double-headed nails.

The Carrillos wrote: “…Removal of the double-headed nail from poured concrete has proven difficult. When removing the forms with a hammer or pry bar, substantial pressure is placed on the forms, which can break the edge of the freshly poured cement.”

Timed Tests

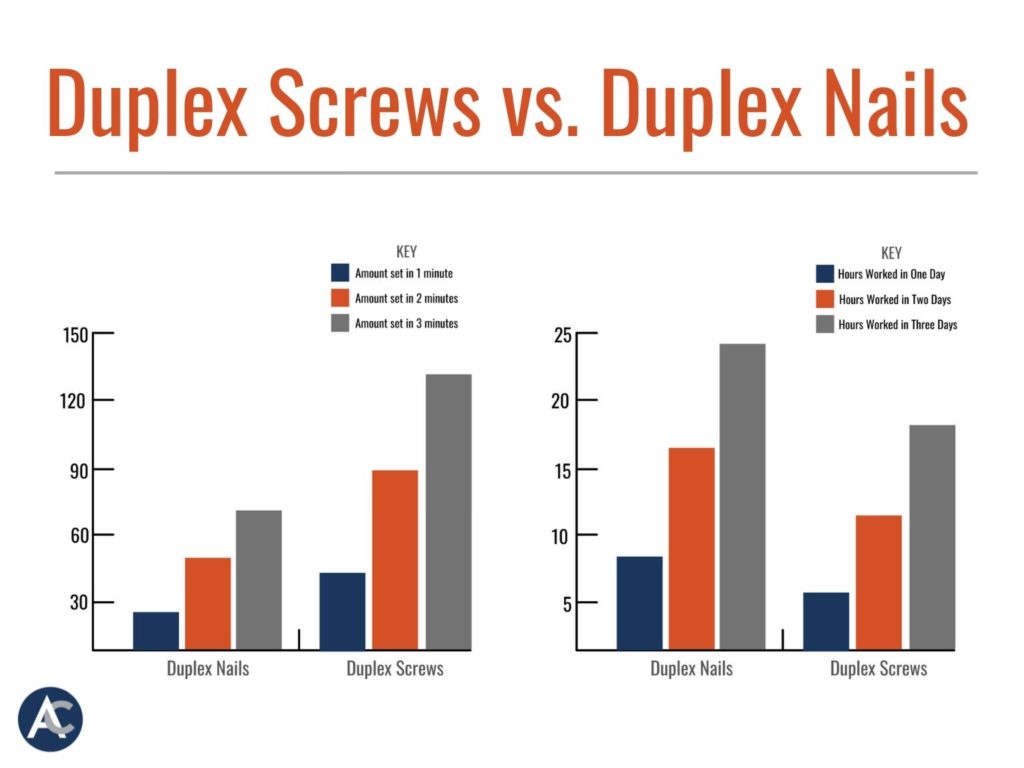

In timed comparison studies, Duplex Screws outperformed Duplex Nails by a wide margin. During three workdays, a pair of concrete-form setters built a 50 x 50 lineal-foot form. One worker used only Duplex Nails and the other worker used Duplex Screws. The Duplex Screw user outperformed the Duplex Nail driver in setting and form stripping – completing the task in six hours vs. eight hours.

In another study, crews were timed for one minute to see how many screws and nails could be installed in the same amount of time. The results showed a 47% difference, with 45 Duplex Screws drilled in versus 24 Duplex Nails hammered in.

Job Safety

Safety on the job site is always a big consideration. Hammers are notorious for causing hand injuries and are among the top four causes of injury in the construction industry. Most injuries involve broken or badly bruised thumbs and fingers. Although some power drills can be quite heavy, they are generally easier to use, and mishaps or injuries are rare.

According to recent reports from the National Safety Council and the Bureau of Labor Statistics, the average hand injury claim can cost from $540 to $26,000 per patient. Lost-time workers’ compensation claims for hand injuries can exceed $7,500. A badly broken finger or thumb can result in more than a month off work and can leave lasting disabilities.

To Hammer or to Drill?

It all comes down to convenience, cost and performance. Duplex Nails are readily available in a multitude of styles and sizes and are sold everywhere. Duplex Screws are only available from select distributors, and come in sizes 1 ¼”, 1 ⅝” and 2 ¾”, and cost more than Duplex Nails. Duplex Screws outperform Duplex Nails and are reusable. All these factors that must be weighed when deciding on what fastener is the right one for the job.

In Stock at Advance

Advance Components is the exclusive distributor of RemoveRite Duplex Screws. We stock a variety of sizes from 1 ¼”, 1 ⅝” and 2 ¾” that ship in 25 lb. boxes. Contact the Advance sales team for more information or buy online 24/7.