“Speed Nuts” are one-piece spring steel fasteners that were developed and manufactured by Tinnerman Products, Inc. Today they are simply called spring steel fasteners as the “Speed Nut” name is not used that much anymore. They were called “Speed Nuts” because they were faster and easier to apply than traditional fasteners. They quickly screw onto screw threads without a wrench or other special tools, and eliminate the need for lock washers because they self-lock onto the screw threads.

Speed Nuts are one-piece, self-locking, heat-treated spring steel fasteners that replace threaded nuts, lock washers and spanner washers. They weigh less than ordinary threaded nuts because they are made of strip instead of bar stock.

History of Speed Nuts

In 1870 George Tinnerman founded the Tinnerman Stove Company in Cleveland, Ohio, where they manufactured high end stoves. In 1936, George’s son Albert created a spring steel fastener – the “Speed Nut” – to solve an on-going issue with shipping stoves. George’s son, also known as George, commercialized the Speed Nut into other industries, and it became so successful that they shut down the stove business.

In WWII, Tinnerman became a supplier of fasteners for aircraft, and in 1947, Fortune magazine cited Tinnerman Company as a disruptor in the automotive industry with the development and usage of spring steel fasteners. The fasteners eliminated the need for riveting and welding, thus speeding up the assembly line and revolutionizing the auto industry forever.

Types of Speed Nuts

There are many types of fasteners that fall under the “Speed Nut” category including Flat type, J-type, and U-type. Each type provides spring tension that absorbs vibration instead of resisting it, ensuring permanently tight attachments.

Flat Type

The Flat-type is the basic design from which thousands of styles of Speed Nut fasteners have been developed. One-piece, self-locking, and heat-treated, the Flat type replaces lock washers and spanner washers. Fast and easy to apply, they provide maximum holding power at a minimum cost per fastener. They never shake loose from vibration, yet can be easily loosened when desired, without worry about rust-frozen screw threads.

J-Type

From the drawing board of the Flat type came the J-Type Speed Nut. Ideal for thin metal applications, the J-type presses easily into a self-retained position over panel edges or in center-panel locations. They are ideally suited for blind assembly or hard-to-reach installations. J-Nuts can be applied after painting or applying porcelain to panels so masking or retapping is eliminated. The short leg of the J-Nut allows for complete visibility of clearance of the hole while the nut is being positioned. They are ideal for blind assemblies.

U-Type

Just like the J-type, the U-type Speed Nut is easy to install, yet it has the extra strength of a lower leg that is ideal for full bearing and flush surface applications. U-Nuts are self-retained in screw-receiving positions to provide simple and fast attachment of mating panels. U-type nuts will not freeze or corrode on threads, and correct misaligned panel mounting holes.

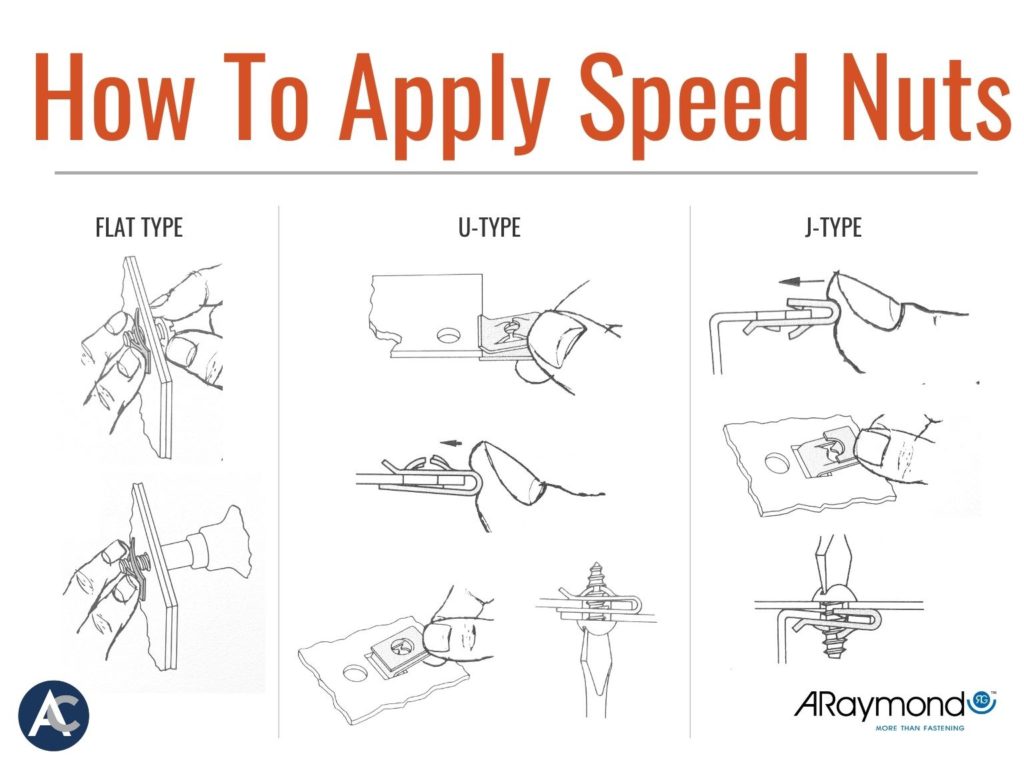

How To Apply

Flat Type Nuts

Hold the nut in the desired position with prongs pointing outward, toward your fingers. Insert and screw the screw into the nut impression. Press the Flat type nut against the panel and drive in the screw. Finger pressure is sufficient to prevent the fastener from turning as the screw is driven.

J-Nuts

Slide the J-type nut over the edge of the panel. Push into position and snap the extrusion into the hole. Place the second panel in position and drive the screw into place. The J-type nut can also be installed in center-panel locations through a rectangular hole.

U-Nuts

Slide the U-type fastener over the edge of the panel or in the center of a panel through a rectangular hole. Push it into position until the extrusion on the lower leg snaps into the screw hole. The U-Nut floats in a screw-receiving position to correct for normal misalignment in panel mounting holes.

Applications and Industries

All types of Speed Nuts are ideal for small components where space is a premium. From the automotive industry to computer manufacturers, spring steel fasteners are the ideal solution for secure connections:

- Electrical assemblies

- Appliances

- HVAC

- Automotive

- Construction

The Speed Nut Today

Since 1972 Advance Components has been stocking and distributing Tinnerman fastening products to distributors and manufacturers in the industrial market. In 2009, Tinnerman was purchased by ARaymond, a 156-year old French-based manufacturing company that develops and makes industrial fasteners and components, and holds over 800 industrial patents. As a master stocking distributor, Advance and ARaymond maintain a strong and successful partnership that our customers depend on. From Flat Type to U-Type, Advance has the stock.